This post is also available in:

![]() PL

PL ![]() DE

DE

THE GLOBAL WORLD OF MANUFACTURING

has been adopting digital technologies for decades.

This digital adoption accelerates as the digital tsunami transforms entire industries.

Over 65% of commercial service robotics projects

achieved payback in under two years.

IDC Industry Spotlight.

Over 70% of commercial service robotics

projects delivered a double digit ROI

IDC Industry Spotlight.

THE CASE

FOR SMART INTRALOGISTICS

Intralogistics is a significant part of industrial value chain affected by labour shortages, operational hazards and obsolete, inefficient technology. Automation of intralogistics has to be efficient, but also flexible. Product personalisation and unpredictable fluctuations of production volumes become important aspects of modern manufacturing challenging traditional intralogistics solutions.

KEY BENEFITS

FROM SMART INTRALOGISTICS

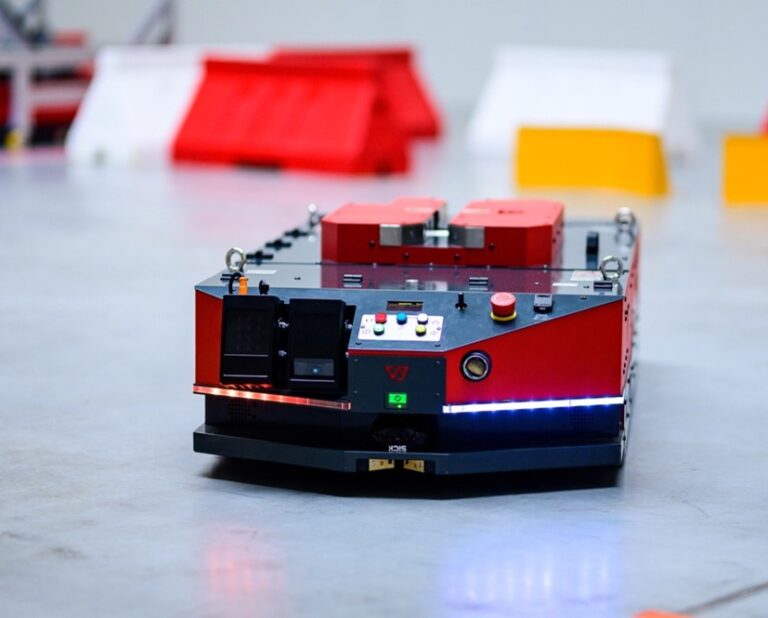

AMR BASED AGILITY

The key capability of SMART INTRALOGISTICS is to quickly and cheaply introduce changes in material flow, to enable changing requirements of manufacturing or warehousing processes. Naturally the flexibility must not compromise fundamental productivity of operations and its cost efficiency. In discrete manufacturing and warehousing the most mature technology that delivers this capability is represented by Autonomous Mobile Robots (AMRs), the most advanced segment of AGVs (Automated Guided Vehicles).

RELIABLE AUTONOMY

This is the capability of executing intralogistics tasks (pickup, transport, handover of materials, components and goods) without human intervention or process related navigational “hard” infrastructure. Human intelligence creates benefits when applied to process optimisation, not to execution of mundane tasks related to transport of material. The “zero infrastructure” requirement is another important enabler of process agility. Autonomous units which are fully self reliant in executing transport assignments, can adopt to changes in intralogistics processes in real-time, without the need for costly and time consuming reconfiguration of beacons, guiding lines etc. In an industrial environment a fundamental requirement for this capability is reliable performance. It is not enough that autonomy works “most of the time”. From the perspective of master process (manufacturing or warehouse management) the reliability and performance of smart intralogistics solution has to match the reliability of all other process automation solutions.

INDUSTRIAL SAFETY

The shop floor is a living environment, with many participants of daily traffic, changing floor layouts and traffic patterns. The autonomous components of intralogistics solution have to cope well with unpredictable behaviour of other traffic participants, enabling undisturbed execution of manufacturing operations. Also, they need to provide uncompromised compliance with industrial standards related to health and safety. Finally – as any digital solution – SMART INTRALOGISTICS requires mature approach to cybersecurity in deployment and operations.

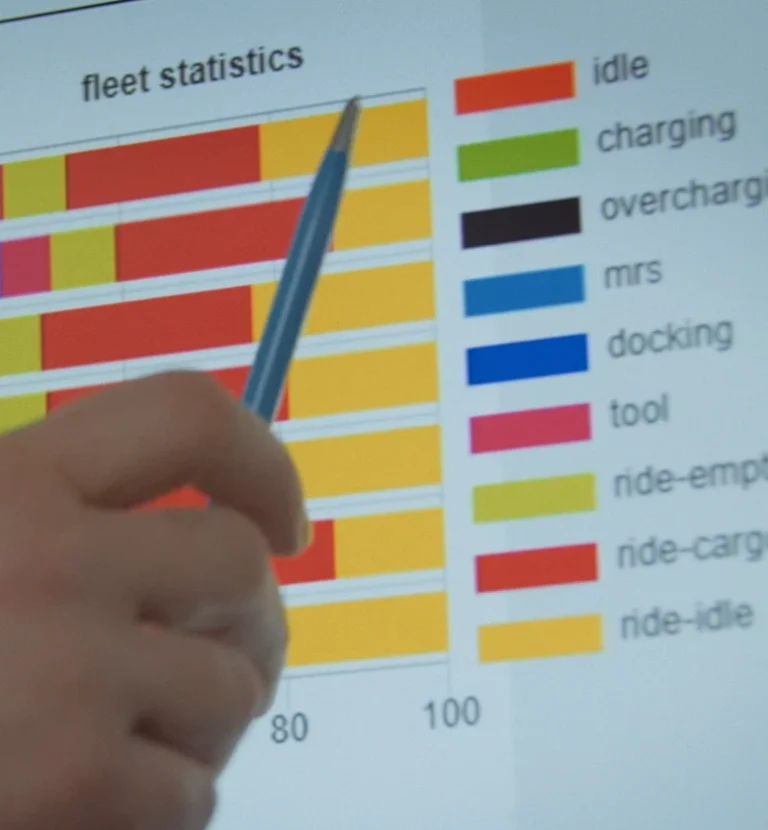

PREDICTABLE PERFORMANCE

This is the capability of simulating and predicting key performance aspects of intralogistics process configuration (such as throughput, cycle times, asset utilisation, energy consumption) without costly, and potentially disruptive experiments on the actual shop floor. This capability is the key to developing and maintaining a positive business case of investment in SMART INTRALOGISTICS solution based on AMRs.

MODULARITY AND INTEROPERABILITY

Truly effective SMART INTRALOGISTICS solution takes more than deployment of smart robots. Essential components of the solution include AMR fleet coordination software (Mulit Robotic System – MRS), simulation environment, and seamless integration with systems governing shop floor operations (MES/WMS/ERP). Well designed SMART INTRALOGISTICS platform enables factory managers to view the intra-logistics as a “Plug-N-Play” process component of their manufacturing operations. Such capability simplifies management and improves the organisations potential for comprehensive digital transformation.

LEARN MORE

Case for Smart Intralogistics

SEE ALSO

What is a smart factory?

Smart factories are an essential part of the so-called fourth industrial revolution (or Industry 4.0). In short, this concept is based on a high level of automation in manufacturing processes, supply chain management, and intralogistics.

Read More

Managing Autonomous Processes & Systems in Manufacturing

There is a labor shortage in industry today, and trends such as "re-shoring" (the return of production processes and industrial plants to developed countries) are exacerbating this phenomenon.

Read More

What is automated guided vehicle – AGV?

Efficient intralogistics is a cornerstone of any manufacturing plant or warehouse. However, high-speed roller conveyors or conveyor belts cannot be installed everywhere – among other things, AGV-type mobile robots are helpful in such situations.

Read More

What is a digital factory?

Digital transformations are a key part of the so-called industry 4.0 business model. One of the most important parts of that, especially for production and manufacturing businesses, are digital factories. What exactly is a digital factory?

Read More

AI in industry

The “smart factory” concept originated from the 4th industrial revolution, also known as Industry 4.0. It emphasizes the integration of advanced technologies such as artificial intelligence, IoT, and automation in manufacturing processes.

Read More

What is an AMR Robot?

Explore the world of autonomous mobile robots - find out what they are, how they work and what they are used for.

Read More