Implementing Smart Intralogistics

VERSABOX WHITE PAPER

THIS DOCUMENT PROVIDES READERS ACTIONABLE INSIGHTS ON IMPLEMENTATION OF STATE-OF-THE-ART, SMART LOGISTICS PLATFORM.

ACTION POINTS:

- ADOPT DATA DRIVEN APPROACH TO SHORTEN TIME-TO-VALUE, MITIGATE RISKS OF PROCESS DISRUPTION AND MAXIMIZE THE RETURN ON INVESTMENT IN AMR TECHNOLOGY.

- PREPARE YOUR ORGANIZATION TO REAP BENEFITS OF SMART INTRALOGISTICS BY RESKILLING EMPLOYEES FOR NEW PROCESS ROLES AND RESPONSIBILITIES

DIGITAL FACTORY AND SMART INTRALOGISTICS

Intralogistics – the area involving internal processing of materials, components and related information – is a significant part of industrial value chain where operations need to change due to labour shortages, operational hazards and often obsolete, inefficient technology. The automation of intralogistics tasks has to meet the growing demand for flexibility of shop floor operations. For this reason manufacturing and logistics organizations are already exploring the benefits of autonomous mobile robots (AMR) as one the key solutions supporting the manufacturing modernization and transformation. VersaBox provides customers with a proven Data Driven implementation process to guide them toward smarter intralogistics.

ASKING THE RIGHT QUESTIONS

Advances in digital technologies enable solutions that are needed to cope with new business challenges faced by manufacturing and logistics organizations. Hyper-optimized value chains, based on “Just-in-Time” logistics and production planning failed catastrophically during early stages of global pandemic, exposing unmitigated operational risks caused by lack of flexibility and diversity.

More flexible processes are becoming a new imperative also due to the increasing demand of personalization and product diversification by the end customers. The era of mass customers and mass manufacturing gives way to the era of mass customization – shorter product lifecycles, variable configurations, variable production volumes.

Finally, one of the biggest opportunities of digital transformation in any industry lies in its skills of collecting quality data and using these digital assets to make better decisions, run better predictions and replace activities on physical assets with advanced information management. Integrating analytical capabilities with automation leads to new breed of automation solutions – more flexible, more autonomous, and more adaptive.

Any organization which understands and appreciates these challenges should start asking itself the following questions:

- Are our intralogistics processes agile enough to cope with substantial variation of flow and content of logistics streams?

- Are we efficiently collecting high quality data to support “evidence based” process management and optimization?

- Are we effectively using advances in information technology to achieve intelligent, autonomous and adaptive process automation – truly smart operations?

VersaBox intralogistics solution has been built to support the modern approach to process automation represented by the above questions.

DATA DRIVEN IMPLEMENTATION OF SMART INTRALOGISTICS SOLUTIONS

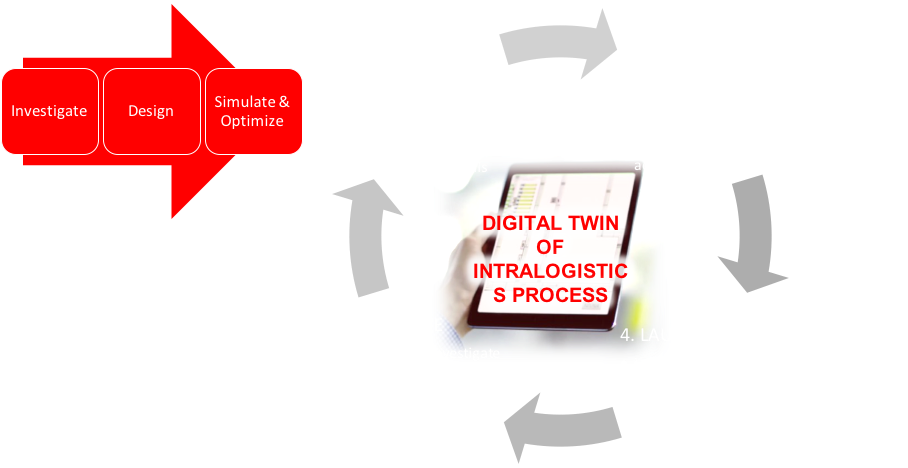

At the core of digital factory concept is digital information. Data generated, integrated and used to better understand and improve the operations based on virtual representations of devices, processes, and systems – their Digital Twins. Manufacturing organizations understand well the value of simulations in product design. Designing and testing new physical components using software is much cheaper, faster, safer and more effective than doing the same with physical components in the physical world. VersaBox brings the same benefits to intralogistics operations management, offering tools supporting Data Driven implementation of smart logistics solution.

The implementation process consists of 5 stages. Initial process definition, performed once, and four stages that form a process management cycle:

- Delivery of solution components

- Integration of solution components

- Launch of the smart intralogistics process

- Evaluation and improvement planning

The following subchapters cover the implementation process stages in more detail.

DEFINE

Data Driven implementation process starts with the preparation of realistic simulation of the new logistics process. This process is directly supported by the VersaBox DIGITAL FACTORY™ simulation and analytics tools. VB DIGITAL FACTORY ™ is a safe and user-friendly environment providing fast, efficient and accurate feedback for managers who want to explore and test multiple scenarios for the smart intralogistics solution. This is a very fast and efficient process – developing and analyzing a scenario with dozens of VERSABOTS and a single floorplan from the scratch takes less than a few days for trained user.

DELIVER

At this stage all the hardware components (VERSABOTS, tools, chargers, docks etc) are being produced, quality checked and delivered to the Client Site. The TRUE AUTONOMY navigation components are preinstalled on VERSABOTS in VersaBox factory.

The software components of the AUTONOMY@WORK platform are being installed and configured for operation by its users, and its process repository is populated with the process definition developed during the DEFINE stage. After the delivery of the hardware this process definition is complemented with all the required data, such as VERSABOTS network configuration or plant mapping.

At the completion of this stage the intralogistics system is ready to be plugged into the master process – manufacturing or warehousing operations. The length of this stage depends solely on VERSABOT production schedules, please contact VersaBox for up-to-date information.

INTEGRATE

To plug in the process into the master manufacturing or warehouse management process, all the software and hardware interfaces need to be connected and tested. Software integration is achieved by using AUTONOMY@WORK open API (Application Programming Interface) – “canned”, safe and well documented software functions which can be triggered using a REST based, secure network protocol by systems such as WMS, MES, or ERP software to activate tasks required from the intralogistics system.

The same mechanism is used for synchronization of robot actions (such as precision docking or cargo pickup/delivery) with PLC components managing machines, automatic shelves, monorail or roller transport systems. This usually involves the alignment and calibration of VERSABOT “tools” – hardware components design to cooperate with various cargo types.

All integrations are tested prior to the launch of the system. The length of this stage is related to complexity of environment and requires detailed planning by the party providing integration services.

LAUNCH

Data Driven implementation process assures that the configuration of the smart intralogistics solution meets the requirements of master process and environment – as long as these assumptions have been adequately provided during DEFINE stage.

EVALUATE

Versabots are data collecting machines. This allows process managers to evaluate the actual process metrics, and compare them with those used for modelling in VIRTUAL FACTORY™. Any discrepancies, or changes of the metrics which are natural for the evolution for manufacturing or warehousing operations, can be reflected in the VIRTUAL FACTORY™ model and used for process improvement.

PROCESS ROLES AND RESKILLING

While autonomous devices eliminate the need for human work in tedious, low value-added transport tasks, the also create new area of human involvement for workers who have appropriate reskilling potential. The key roles required for well running, AMR based, intralogistics include:

- Intralogistics Process Manager – uses the AUTONOMY@WORK™ analytic and simulation capabilities to generate insights for process improvement and optimization, as well as for planning

- Fleet Manager – manages all the activities related to maintain operational readiness of the fleet, such as spare parts stock maintenance, versabot lifecycle management, upgrades and maintenance inspections etc.

- Fleet Engineer – using AUTONOMY@WORK™ and TRU AUTONOMY™ open APIs, develops solutions for integrating versabots and AUTONOMY@WORK™ with specific devices and systems.

The new roles may represent attractive career paths for intralogistics and IT specialists.