Customers

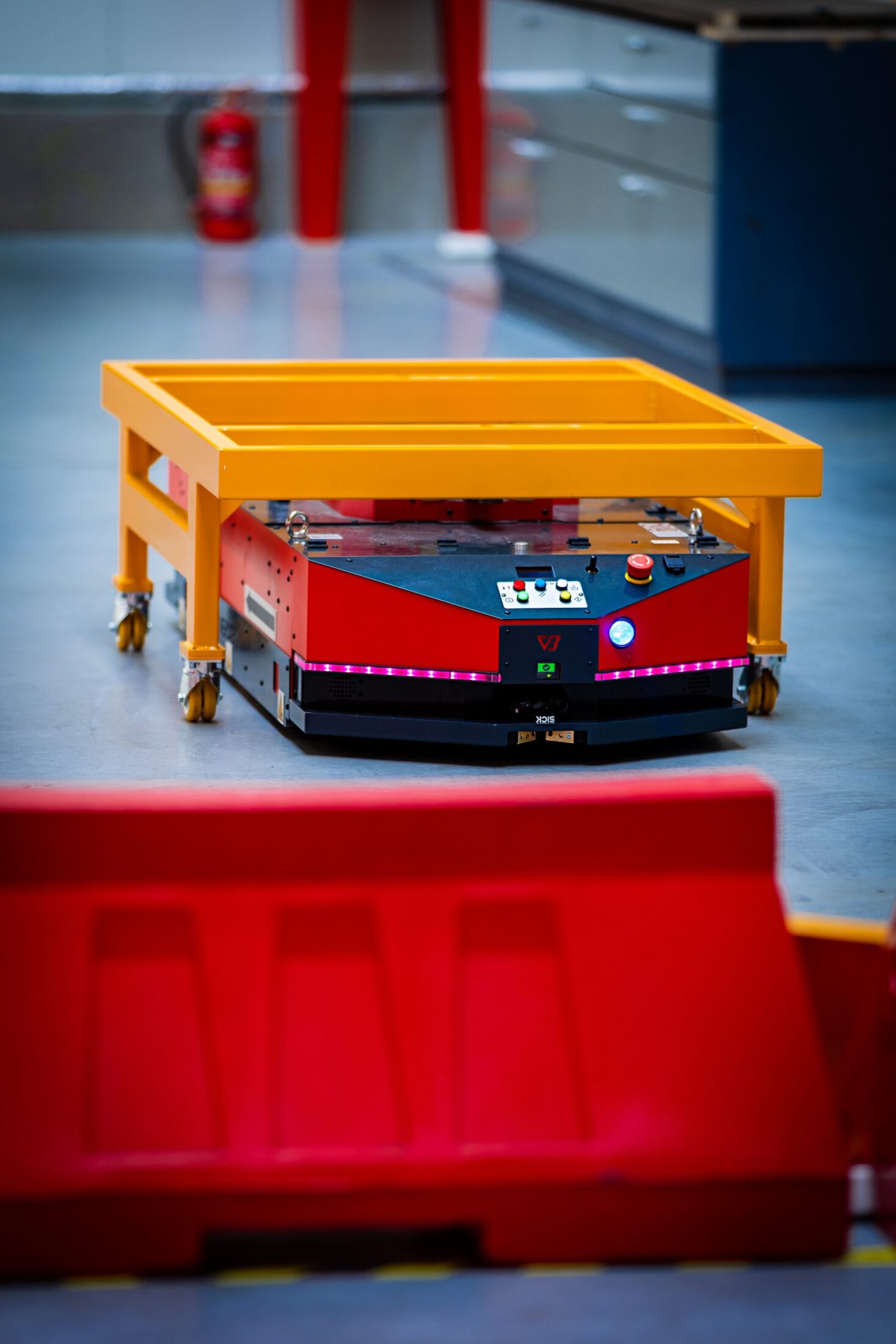

VersaBox offers comprehensive, end-to-end solution for AMR based automation. Browse the catalog to access the specification of software components, AMR platforms, tools (top modules) for different processes and payload categories, and power supply solutions.

VERSABOX clients are fast adopters of for technological innovations, seeing them as a tool for building business efficiency and competitive advantage. They often implement extensive modernization and process improvement programs, in line with Industry 4.0 framework. The leaders of these programs are experienced innovators pursuing digital leadership in their industry.

The constantly growing community of VERSABOX customers represents various industries related to manufacturing: automotive, food industry, packaging, machine industry. VERSABOX solutions are particularly well suited to difficult industrial requirements – from reliable navigation in the dynamic shop floor environment, through industrial design for heavy duty operations, to adherence to safety standards.

Selected customer stories

Implementations of VERSABOX solutions carried out by clients include both end-to-end intralogistics processes and the automation of selected missions contributing to the transport process. The focus is always on achieving business goals, addressing challenges, and delivering meaningful results. Below are some customer stories representing cases of varying scale and scope.

Please contact us, we will be happy to answer your questions and prepare an interesting offer.