AUTOLIV

AUTOLIV Factory

Autoliv is a leading supplier of safety systems for passenger cars. The recipients of the company’s products are major car manufacturers in the world, incl. Opel, Ford, Mercedes, Volkswagen, BMW, Saab or Renault. Autoliv mission is to save human lives, and the company entrusts the implementation of these goals to well-trained and creative staff.

Ensuring pickup and transport efficiency at the end of the production process in line with the pace of production line output cycles.

Ensuring a smooth x-ray inspection process synchronised with production cycles.

Challenges

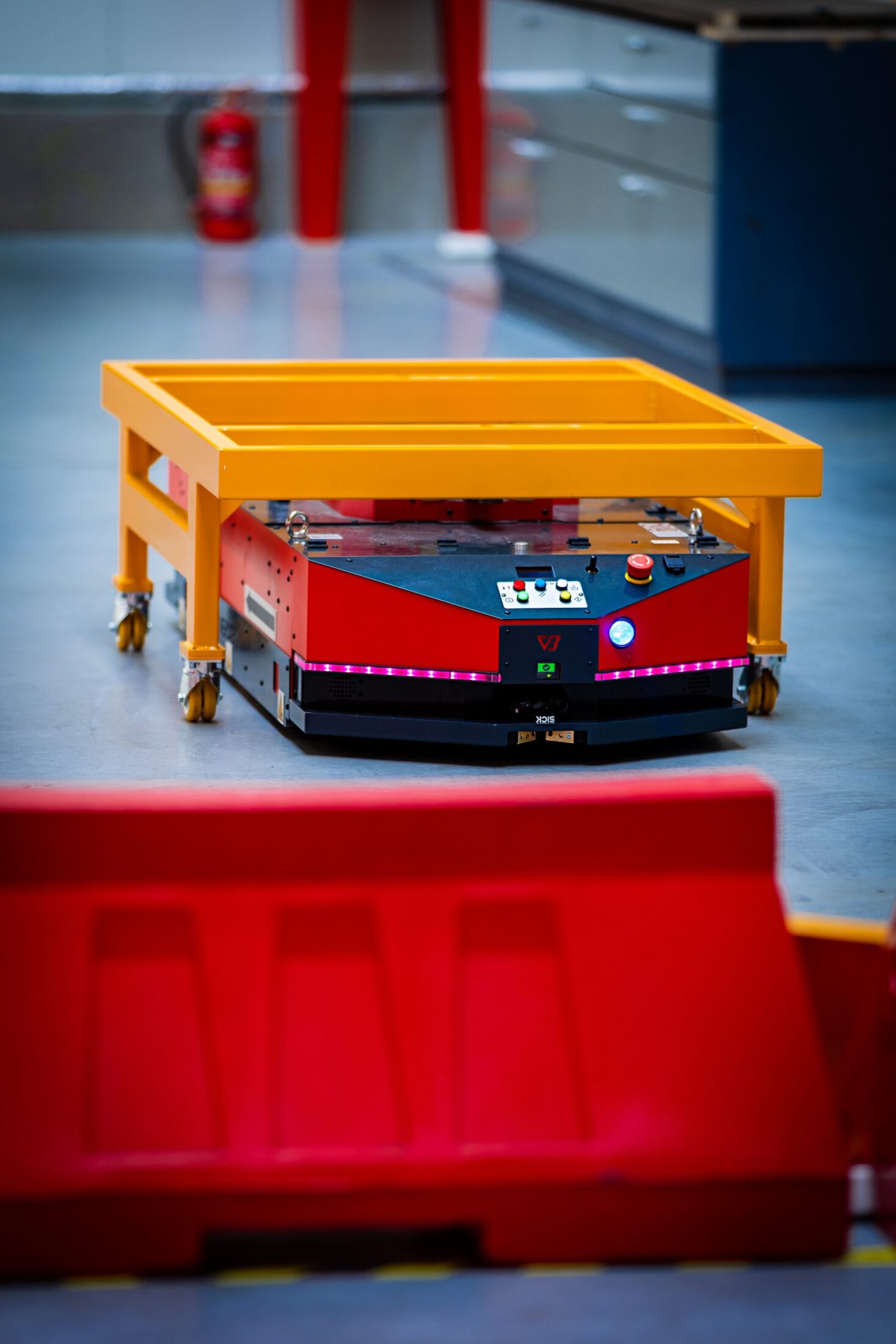

The mission of saving human life is obliging. Autoliv rigorously verifies the quality of airbags – this stage is an important part of the value chain. Transport automation for this stage has its own specific requirements resulting from the production process. It requires the integration of three logistic streams between the production line and the X-ray inspection station.

- The end of the production line consists of three parallel roller conveyors. The chamber in which the quality of the products is tested is supplied from one feeder. Efficient transportation required a custom tool to “concurrently” pick up products and “sequentially” submit them for inspection.

- Transport and docking take place on a busy traffic route. Transport equipment must not hinder the movement of workers or pose a threat to them.

- VERASBOT shares the route with the traffic of logistic trains. An important challenge is the cooperation between automatic and traditional transport.

Communication with the PLC system ensures full synchronization of the receipt of products from the line by VERSABOT with the production cycle.

Thanks to the autonomy of the VERSABOTs, disruptions between the automated transport process and the movement in the factory were avoided, with the availability of the system 24×7. At the same time, robot safety mechanisms completely eliminate threats to people and other devices.

The combination of creativity and knowledge of Autoliv engineers, with the VERSABOX product versatile design has been a key enabler of successful implementation. VERSABOTS are engineered for easy adaptation to smart terminals of the production lines. The result is a unique (and more importantly – effective) solution, optimally using the advantages of VERSABOTs. Due to these positive experiences, the use of the VERSABOTs is also planned after the production has been transferred to the new factory in Jelcz.

MATEUSZ WIŚNIOWSKI

Head Customer Success, VERSABOX