Autonomous mobile robots in intralogistics. Trends and possible applications

When we talk about the use of autonomous mobile robots (AMRs), we usually think of warehouse or a production facility. This is due to the fact that industry and logistics generate the greatest demand for AMR-class machines. However, the uses of autonomous systems are much broader. In the near future, AMRs will be present in all areas of the economy, and even everyday life.

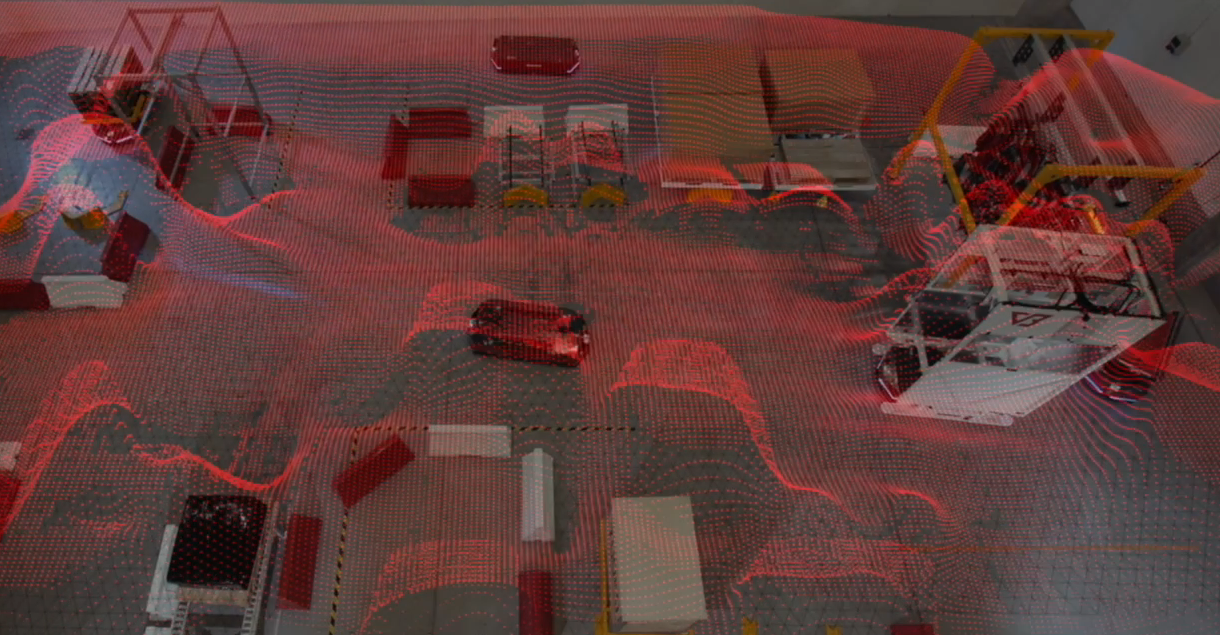

The current most popular AMR model is a small, low suspension transport platform.

Automated guided vehicles – universal platform plus attachments

VersaBox is a provider of autonomous mobile robots to help your company optimise its intralogistics processes. The design of AMRs, such as VERSABOT 500 and VERSBOT 1000, is dictated by the working conditions in warehouses and production facilities. Automated guided vehicles with very low suspension are perfect for narrow storage aisles and tight spaces in production halls. The robot itself is a type of power unit that can be equipped with various types of attachments and modules and which can communicate with the mobile platform through a dedicated API. Currently, VERSABOTS offer four types of attachments provided by VersaBox:

- coupling module – allows the robot to attach itself to platform or basket transport trolleys that have their own wheels,

- lifting module – allows the robot to collect and deposit pallet loads, using stands that enable it to drive under the pallet, lift it and transport it,

- roller feeder module – attachment for collecting loads from roller conveyors,

- frame transport module – adapts the robots for work with monorail conveyors when transporting frame elements.

“AMRs currently in use in the industry are small transport platforms. However, you have to remember that the robot is just the “tip of the system”, the heart of which is the software that runs the entire fleet of robots, known as the Autonomy@Work intralogistics platform,” says Rafał Jagielski, R&D manager at VersaBox, which produce AMR-class robots.

“We currently offer two models of AMRs: VERSABOT 500 and VERSABOT 1000. However, if necessary, other transport machines can also be connected to the Autonomy@Work software. It can be a forklift or any kind of self-propelled platform for transporting machine elements, oversized steel products, or new cars from the production line to the warehouse.”

In practice, all kinds of attachments can be developed to enable VERSABOTS to perform specific transport tasks. It is also possible to combine many functionalities in one machine. An AMR, whose primary use is the transport of pallets, can support other processes in a given facility during its breaks. All this to make the most of gaps in work. Robots do not need to rest – they work non-stop with consistent precision and efficiency. The only downtime is during charging, but even that is woven into the stations where the goods transported by the robots are handled. Other robots immediately take over the tasks of the robot that is currently charging.

Warehouse and production hall automation is not the be-all and end-all of possibilities of using autonomous mobile robots. Non-industrial applications are still a great, untapped potential.

AMRs to enter schools, hospitals, airports?

The decision to use autonomous mobile robots depends largely on the speed of return on investment. In industry, this time is relatively short. After less than two years, and AMR starts to bring in very tangible profits. The use of AMRs outside of the industry is not a technical issue, but a problem of lack of awareness of the financial benefits of such an investment. For now. However, over the next few years or more, the situation may change dramatically. There are numerous areas of the economy where robots may appear:

- hospitals – delivery of meals and medicines, transport of equipment and patients, cleaning, disinfecting;

- hotels – food delivery, cleaning (as an accompanying trolley, a vacuum cleaner, and transport of cleaning products), disinfection, luggage transport, informative and monitoring tasks;

- airports, sports halls – luggage and passenger transport, cleaning, informative tasks;

- schools – cleaning, disinfection, monitoring;

- supermarkets – stocking, quick control of number of products in stock, transport between the shop floor and the warehouse.

These are just some of the more obvious examples of possible applications of autonomous mobile robots. Robots fleet management systems are already sufficient to accomplish these tasks. The physical design of the robots would require some changes to adapt to the new working conditions. A tortoise lookalike or an autonomous vacuum cleaner, if you prefer, is not enough everywhere. Does that mean the appearance of humanoid AMRs? If a robot is supposed to support humans at work, why should it not look like one?

“We aren’t surrounded by humanoid robots because there is currently no practical justification for their existence,” says Rafał Jagielski. “Creating robots that look human is intellectually alluring idea and direction of development, but it’s impractical aside from a few rare cases. Suffice to say that the first plane was successful only when engineers stopped trying to imitate birds. Robots don’t have to imitate people. They evolve according to their own rules. On the other hand, futurology made history mainly due to spectacular failed predictions, so maybe we shouldn’t be so quick to rule out the creation of androids. Regardless of what they look like, it’s certain that the numbers of autonomous machines will continue to grow rapidly.”