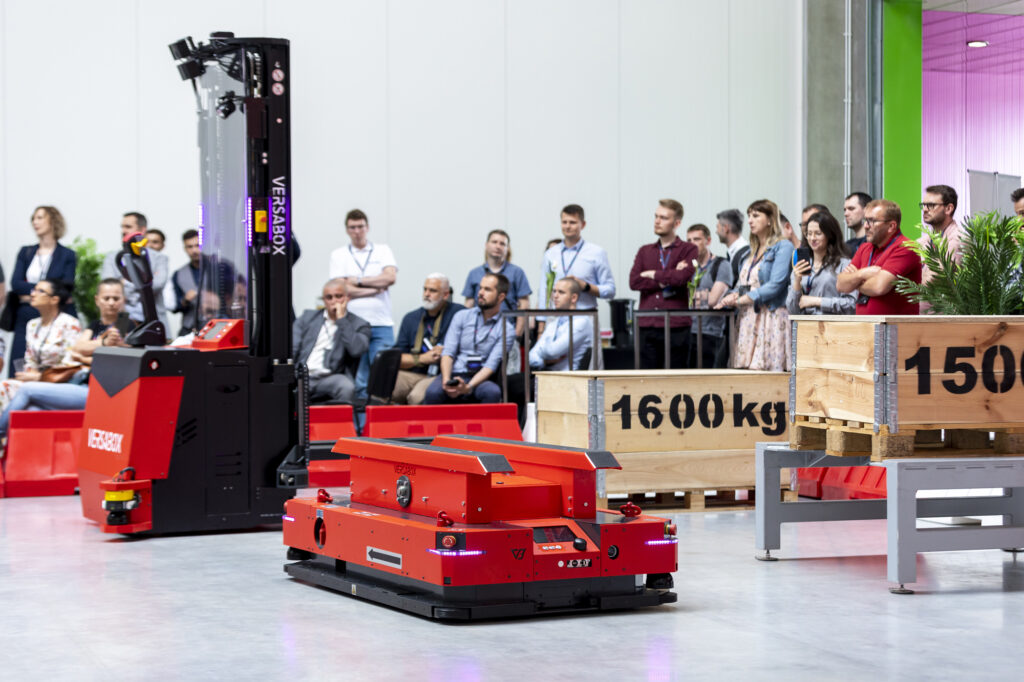

MEET VB1500

VERSABOT 1500 is a new AMR offered by VersaBox. It has a lifting capacity of 1500 kg that far exceeds the capabilities of its smaller brother, VERSABOT 500, which has a lifting capacity of 500 kg (it can transport loads up to 1000 kg on trolleys). It’s worth emphasising that VERSABOT 1500 is based on solutions and technologies tested and proven in the previous model.

“We are proud of the fact that we have managed to significantly expand the possible uses of the robot, and at the same time maintain a compact design with only slight changes in size,” says Michał Walęcki, Chief of Engineering at VersaBox. “VERSABOT 1500 is only 5 millimetres taller and 20 centimetres wider, but at the same time it’s about 20 centimetres shorter. We have created a “heavyweight” that, at first glance, doesn’t differ significantly from its much lighter predecessor.”

The full dimensions of VERSABOT 1500 are 1510 x 925 x 310 mm (length x width x height). It weighs 460 kg. However, this doesn’t negatively impact its excellent manoeuvrability or speed. Their operation time hasn’t changed either – despite the significantly increased load capacity, they can still operate for up to 10 hours on a single charge.

A harmonious blend of power, independence, and agility

VERSABOT 1500 offers a load capacity characteristic of many electric pallet trucks or forklifts. At the same time, it also has the advantages of an AMR. First of all, it’s completely autonomous and requires no operator support – neither direct nor remote. TRUE AUTONOMY™ uses elements of artificial intelligence for independent movement and for nimble avoidance of obstacles (both static and dynamic ones). Thanks to this, the robot only needs predetermined destination points (for collection and delivery) to performs its transport tasks, while any challenges that arise along its route are solved independently.

Autonomy also includes monitoring the battery status and the robot goes to the automatic charging station when it deems it necessary. It can do it after finishing its “daily shift” or as a series of short top-ups during breaks between performing transport tasks. It is also possible to replace the battery without turning off the robot. This saves us time: it takes only about 30 seconds. It achieves optimal results by combining its own autonomy and the capabilities of the fleet management system. The system coordinates the work of all VERSABOTS currently engaged in transport tasks.

Like its smaller predecessor, VERSABOT 1500 has a modular design. This allows for quick adaptation to specific working environment conditions and user requirements. Another huge benefit is that it makes repairs much shorter and easier to carry out. A properly organised maintenance service means no problem of downtimes associated with machine failures.

The new generation of VersaBot robots are designs with an exceptionally good load-to-agility balance. Despite its maximum weight with a full load being almost 2 tonnes, VERSABOT 1500 is a highly manoeuvrable and nimble AMR. It has a small turning radius. Thanks to its to relatively small size, it’s easy to manoeuvre even in very narrow warehouse aisles.

VB 1500 platform is provided with two standard smart tools – lift and roller. As with all VERSABOX AMR platforms, we are ready to address specific load requirements with a custom designed smart tool.