VersaBox Blog

Best practice – white papers – inspirations – case studies

Articles

12.08.2023

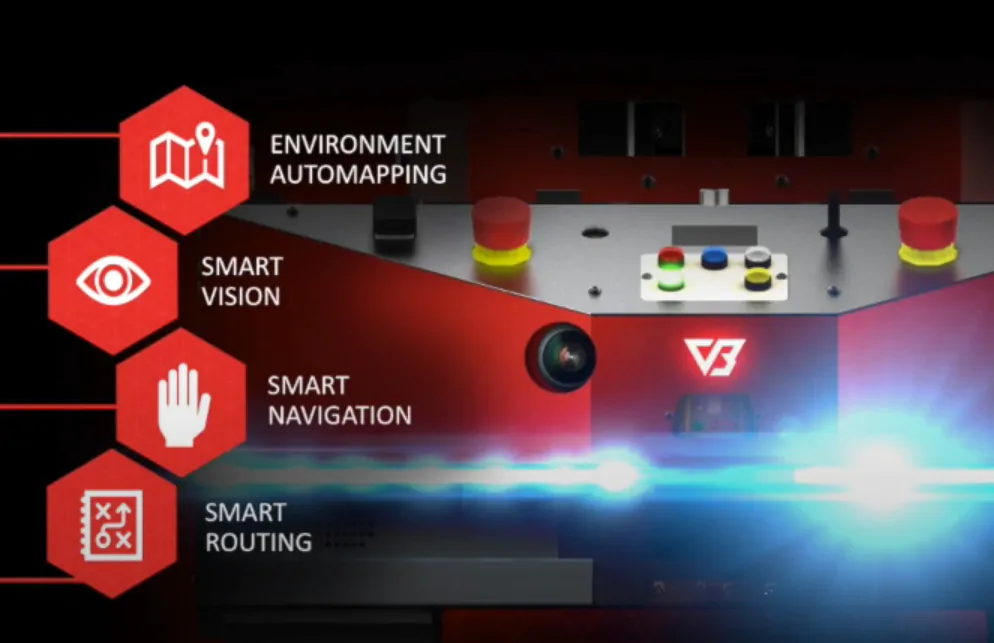

AMR Technology

GENERAL

SMART INTRALOGISTICS

13.04.2023

GENERAL

16.03.2023

AMR Technology

INDUSTRY 4.0

SMART INTRALOGISTICS

15.03.2023

SMART INTRALOGISTICS

WAREHOUSE AUTOMATION

15.03.2023

SMART INTRALOGISTICS

WAREHOUSE AUTOMATION

15.03.2023

INDUSTRY 4.0

SMART INTRALOGISTICS

18.02.2023

GENERAL

WAREHOUSE AUTOMATION

17.02.2023

GENERAL

INDUSTRY 4.0

WAREHOUSE AUTOMATION

15.02.2023

GENERAL

SMART INTRALOGISTICS

14.02.2023

GENERAL

INDUSTRY 4.0

SMART INTRALOGISTICS