VICTAULIC

About Victaulic

Victaulic is a global leader in solutions for infrastructure, industry, and construction, recognized for its innovative approach to design, manufacturing, and process optimization. The company specializes in the development and production of pipe joining systems, couplings, fittings, and installation solutions used in fire protection systems, water installations, industrial applications, energy, and HVAC.

Victaulic products are deployed in some of the most demanding projects worldwide, where reliability, safety, and durability are critical. The high technological complexity of these products directly translates into complex manufacturing and intralogistics processes within Victaulic’s production facilities.

Business goals

Victaulic’s objective was to optimize internal transport processes between production areas and warehouse zones while maintaining the highest levels of operational reliability.

Stable and predictable flow of heavy loads

Continuous movement in a dynamic production environment, where any disruption in internal transport could directly impact production continuity and operational safety.

Optimization of complex internal logistics processes without interrupting ongoing production, while reducing reliance on manual transport and improving coordination between production and warehouse operations.

Challenges

Victaulic plants operate in highly demanding industrial environments where operational reliability, uninterrupted production, and precise logistics coordination are essential. Handling heavy components and maintaining intensive material flows require solutions that are efficient, safe, and flexible.

Operating in demanding industrial conditions

The production environment at Victaulic involves heavy components, continuous operations, and challenging industrial conditions, requiring transport solutions capable of maintaining reliability and performance without compromising safety or uptime.

Connecting multiple production and warehouse areas

Material flow at the facility spans across several production zones and warehouse areas, making it essential to coordinate transport processes between different locations while maintaining smooth and uninterrupted operations.

Ensuring safety standards and process repeatability

With frequent movement of heavy loads and human presence on the shop floor, maintaining high safety standards and ensuring consistent, repeatable transport processes was a critical challenge.

Integrating with existing infrastructure and production processes

The new transport system had to be seamlessly integrated into existing production lines and intralogistics infrastructure, without disrupting ongoing operations or requiring major changes to established workflows.

Solution

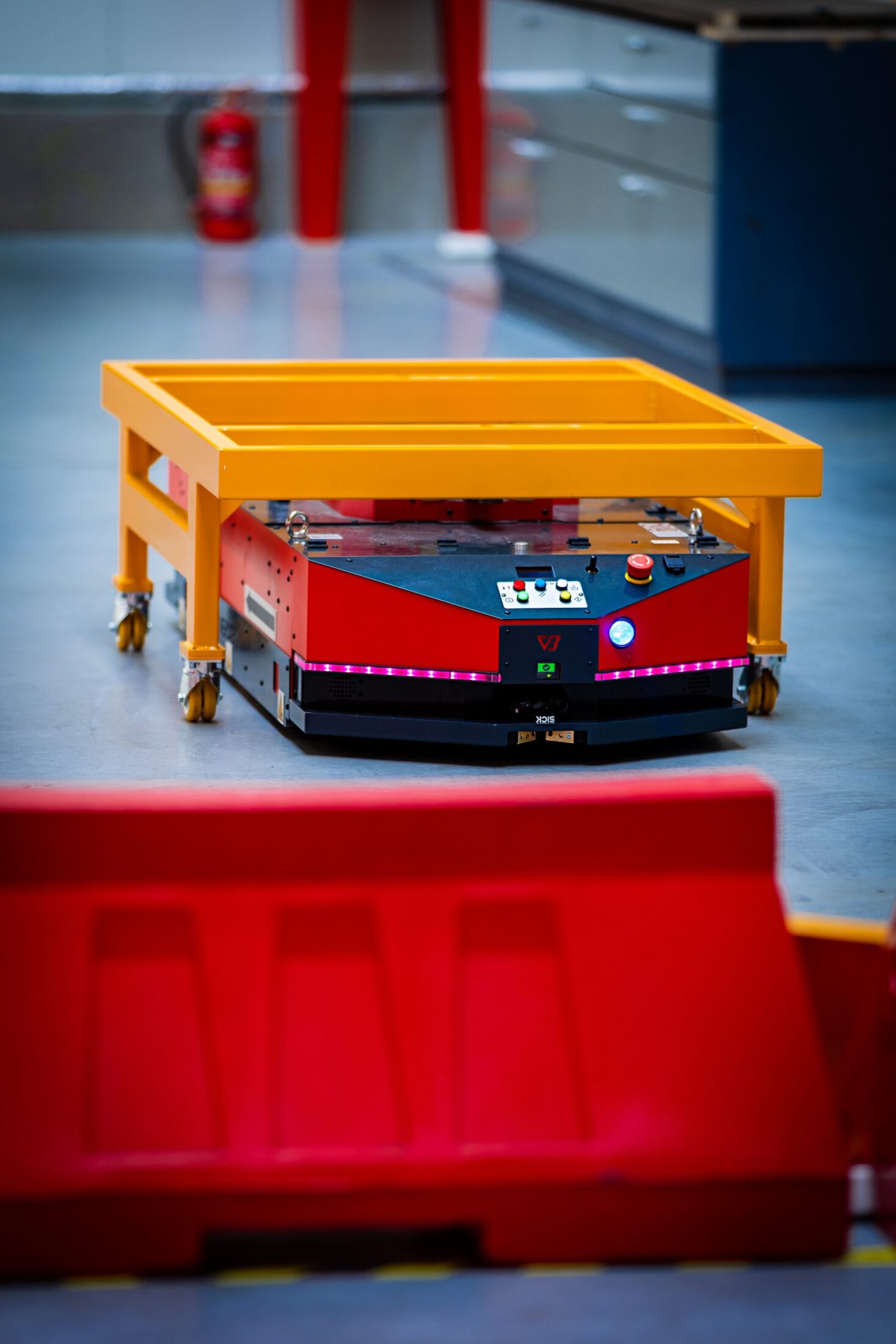

As part of the project, Versabox implemented Autonomous Mobile Robots (AMR) with a payload capacity of 1,500 kg, specifically designed for heavy-duty industrial applications.

The AMR system connects production areas with warehouse zones and supports continuous internal transport operations. Each robot ensures a stable and efficient flow of materials 24/7, both between production and storage and across individual production stations.

The robots operate in cooperation with roller conveyors, creating a fully automated intralogistics process. During the design phase, multiple automation scenarios were modeled to develop an optimal configuration of robots, routes, and system logic tailored to Victaulic’s operational requirements.

Results

Stable material flow between areas

Autonomous Mobile Robots ensure a consistent and reliable flow of materials between production lines and warehouse zones, eliminating transport bottlenecks and supporting continuous manufacturing operations.

Uninterrupted 24/7 operation

The AMR system operates continuously around the clock, maintaining transport availability regardless of shift schedules and ensuring uninterrupted support for production processes.

Reduced risk of errors and unplanned downtime

Automation of internal transport minimizes human-related errors and reduces the risk of unexpected downtime caused by manual handling or inconsistent transport processes.

Improved workplace safety

By automating the movement of heavy loads, the solution significantly reduces manual handling and vehicle traffic on the shop floor, improving overall safety for employees.

Seamless integration of AMRs with roller conveyor systems

The AMRs work in full synchronization with roller conveyor systems, enabling automated handover of loads and creating a cohesive, end-to-end intralogistics process.

Turning innovation into autonomous operations ...

Victaulic is committed to innovation, proving that digital transformation and process automation are possible even in the most demanding industries. Versabox models various automation scenarios to design an optimal, autonomous logistics ecosystem. At Victaulic, we implemented an AMR system that connects production and warehouse areas. By integrating Versabots 1500 with roller conveyor systems, Victaulic achieved a fully automated logistics process — delivering reliability, stability, and repeatability.

Filip Jóźwiak

Senior Technical Sales Consultant

See other cases