CUT COSTS WITH AMR

Which tasks can be entrusted to autonomous transport robots and what can be gained from it? These and many other questions were answered during VersaDay Robotics Innovation Summit on June 8 at VersaBox headquarters in Warsaw – in other words an open day at VersaBox, a manufacturer of autonomous industrial robots.

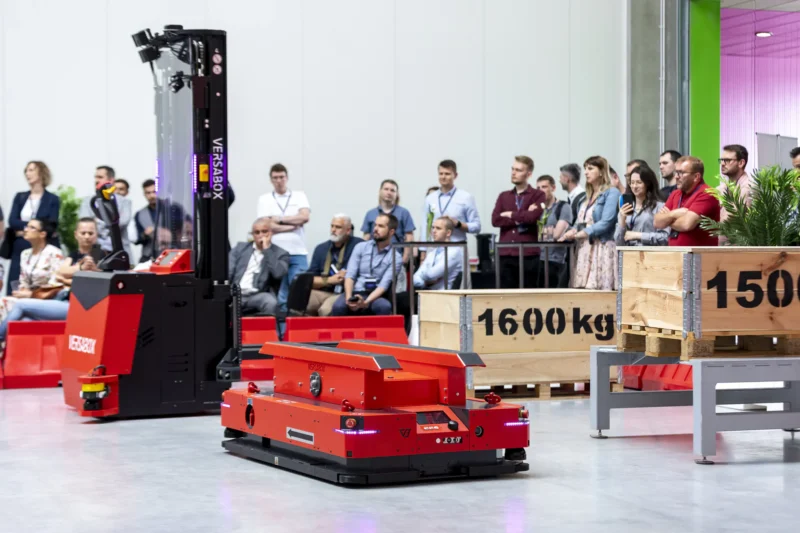

The hall at Jerozolimskie Avenue 211 was filled with almost 150 customers wanting to see for themselves what the benefits the use of autonomous transport robots, designed by the Warsaw-based technology company, could bring to their companies. VersaDay Robotics Innovation Summit was a fantastic opportunity to learn more about the potential that these smart and innovative machines offer, both in terms of improving internal logistics and cost optimisation.

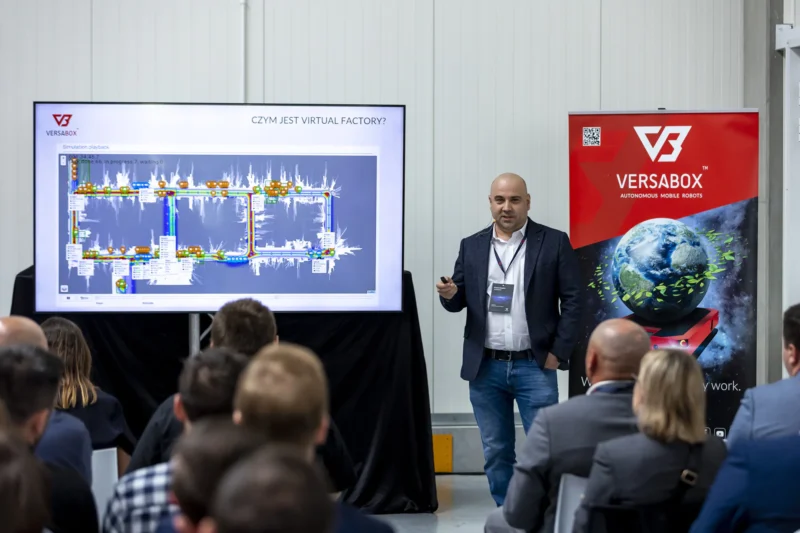

The meeting was inaugurated by VersaBox CEO Jacek Królik and first on the agenda was a presentation of the VersaBox Virtual Factory, a virtual simulator of intralogistics processes. This is a proprietary tool that distinguishes VersaBox on the industrial robots market. The program enables the customer to accurately understand the scope, optimal application, efficiency, costs, and depreciation of their autonomous intralogistics transport system – and as a result make a rational business decision based on specific data.

Research conducted by International Data Corporation shows that in the case of a Versabot the return on investment occurs after less than two years of use. Paweł Oziębło, Head of Value-Added Services in VersaBox, talked about how the VersaBox Virtual Factory works. Szymon Kubicki, who is the Sales Director in Poland, showed the guests how a digital transformation of an intralogistics process works based on the real-life example of an implemented system at the Padma furniture company, an IKEA network partner.

During VersaDay Robotics Innovation Summit, invited experts shared their knowledge in the field intralogistics system automation safety (ELOKON Polska) and financing opportunities (CRIDO). The event ended with a demonstration of transport robots and a shared lunch, which was an opportunity to exchange impressions and experiences.

VersaBox, as a technology company, organises many events promoting knowledge about the innovations in the field of industrial robots. The company’s proprietary product, which stands out on the market with its advanced software and use of artificial intelligence, has already met with great reception from customers in Poland and has proven itself in practice in companies such as Maspex, Faurecia, Padma. Due to favourable conditions for development – rising labour costs, shortage of employees for repetitive and mechanical tasks, increasing digitisation – VersaBox plans to expand into foreign markets as their next step. The demand for these types of solutions will grow, which is also influenced by phenomena such as an ageing population, the expected return of manufacturing to Europe and thus demand for locally made, advanced systems. The company estimates that the industrial robots market in Europe is currently worth around EUR 0.5 billion and will grow to over EUR 2 billion by 2027.

Some of VersaBox’s existing customers operate in multiple countries aside from Poland, as is the case with Faurecia where the autonomous transport robots system is already in use in its Czech factory. This product fits perfectly into the global trend of industrial automation, dictated by both the dynamic development of digital technologies as well as the need to optimise costs and processes. Therefore, VersaBox plans further dynamic development of the offer itself, as well as expansion into new markets.

The interest and presence of almost 150 customers at VersaDay Robotics Innovation Summit proves that the Warsaw-based company has every chance to become an industry leader.