This post is also available in:

![]() PL

PL

Factory managed from the cloud. Is it safe?

The effective management of industrial processes, including Autonomous Mobile Robot (AMR) intralogistics, requires efficient acquisition, transmission and distribution of data. By far the best (read: the simplest, the fastest and the cheapest) solution is to use cloud computing. However, it’s still often treated with caution, resulting from concerns about the security of company data. Are these doubts reasonable?

One of the important issues that arises in connection to migrating to the cloud is an attempt to find out where company data will actually be, and will it be safe there?

In the cloud, meaning where?

The cloud is the ability to use computing power and storage space as part of a periodic subscription (depending on the service and its provider, it can be determined based on the number of users, the size of the transfer, or the amount of disk space). To store data, you purchase space on the server. If you also want to process the data – you buy the right to use the appropriate applications (or platform with applications).

All data storage and processing operations don’t happen at our desk, in our own computer, but are carried out by a gigantic infrastructure of data centres located all over the world. These are owned by companies such as AWS (Amazon Web Services), Microsoft, Google and IBM – currently the largest providers of services collectively called cloud computing. Of course, the cloud can be synchronised with folders on our computer, which means the data will also be available offline.

Why is the cloud cheap and secure?

All the advantages of the cloud have a common feature – you get access to storage space,

computing power and software at a disproportionately low price compared to the construction of your own IT infrastructure. Here are the three most important benefits of building an IT infrastructure in the cloud instead of in real life:

Cheap power and software – you don’t have to buy hardware or software licenses (no need to pay for software updates, you’re always using the latest versions), you don’t need to lay expensive network cables, allocate and equip server rooms, create jobs in the IT department, and a host of other operations. As part of the subscription, you get access to the always ready for use power of virtual machines.

Easy scalability – computing power, storage space, and software package can all be easily adapted to your current needs. Instead of buying new computers and licenses, you increase your subscription level – if there’s a need to withdraw from a project, the costs will be minimal (because starting costs were minimal) and you won’t be left with a pile of unnecessary equipment.

Maximum security – your data will never be as well protected (against hardware failures, viruses, management errors, unauthorized access) as in the cloud. Most companies don’t have sufficient resources to create a similar level of security in their own network.

When talking about data loss, we usually think about a cyberattack. In reality, however, a power surge or a disk array failure may be a far greater threat, either of which could make it impossible to access data for a long time, or in extreme cases cause irreversible loss. The cloud protects you against such threats – even the physical destruction of one of the computing centres (e.g. as a result of a natural disaster) doesn’t threaten your data, because copies of it are stored in many different places. Most often, you don’t even get a chance to notice there was a failure – functions of the damaged equipment are taken over “on the fly” by equipment that contains a copy of your data.

How does the cloud manage production processes securely?

Managing production processes, including intralogistics based on AMRs, is much more convenient and secure when done with cloud computing. Why? First of all, because of its failure-free operation described above. Secondly, cloud computing allows access to management systems from anywhere in the world, at any time, without the need to be where the robots are located. You can manage it all from any mobile device – the only condition is access to the Internet.

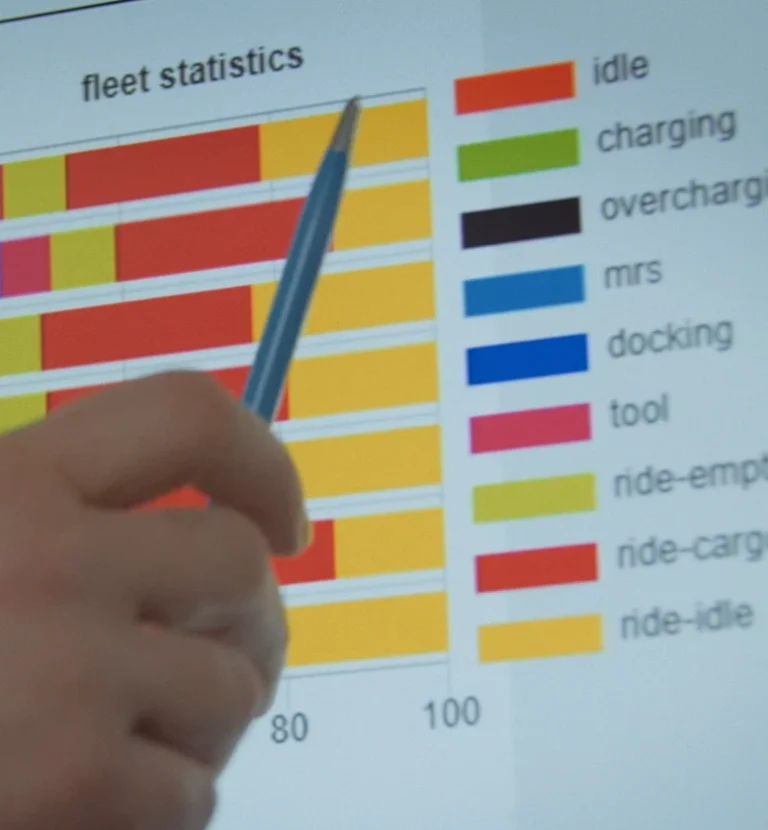

The cloud not only enables efficient collection of process data, fast processing and distribution in the form of reports or alerts, but also real-time process monitoring. Thanks to this, it’s possible to conveniently and efficiently manage the implementation of tasks carried out by AMR robots – you can monitor them, change their parameters, suspend and run them remotely. You also have direct insight into the current technical condition of robots. This can significantly reduce service response time. The person supervising the robots is immediately informed of each recorded irregularity. Replacing corrective (or interventional) maintenance with predictive maintenance allows for the optimisation of service costs and an overall increase of the efficiency of maintenance services.

Virtual models save real money

Implementing AMRs or any other solution (e.g. assembling a production line) doesn’t have to be done using the traditional approach, i.e. moving from the project level directly to the implementation phase. An alternative approach is to set up a virtual, i.e. in the cloud, production line or logistics system supported by AMRs and people. Here, virtual counterparts of physical machines are used. A good model allows you to conduct tests and optimise the operation of the entire system before implementing it in a real warehouse or factory. The costs of such operations are disproportionately low compared to building a physical production line or optimising a logistics system in a real warehouse.