Virtual Factory

VERSABOX VIRTUAL FACTORY™ is a process design and simulation tool for operation managers and intralogistics specialists. Offers modeling, visualisation and evaluation of AMR-based intralogistics processes. Component of AUTONOMY@WORK™ platform, available also as an independent functionality.

VERSABOX VIRTUAL FACTORY™ is one of the key tools supporting data driven implementation of the AUTONOMY@WORK™ platform. It enables operation managers and intralogistics specialists to model, evaluate, and optimise the configuration of AMR-based intralogistics processes. While an integrated component of the AUTONOMY@WORK platform, it may also be used as a standalone tool by organisations that are still evaluating the business case for smart intralogistics.

Key functions

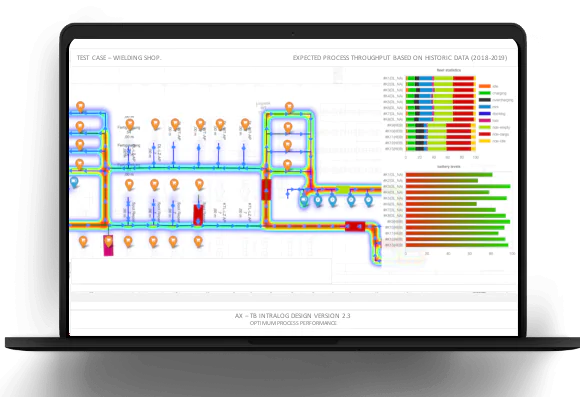

VERSABOX VIRTUAL FACTORY™ provides operation managers and intralogistics specialists with insights in the form of interactive, visual simulation of intralogistics traffic. The interactive analytical capabilities include:

- Realtime Heat Maps visualising event intensity patterns for aspects such as corridor traffic, slowdowns, deadlocks, MRS interventions, etc.

- Configurable KPI Dashboards providing core KPI information on fleet utilisation, energy usage, endpoint traffic at every time-point of the simulated intralogistics process.

- Model Interaction – filtering and managing the level of details: zoom in and out to analyse the global picture or a specific part of the process layout, as well as include/exclude the building blocks of the process model (endpoints, paths, zones, etc).

VERSABOX VIRTUAL FACTORY™ can use either existing factory layouts available in popular DWG format, supported by many CAD tools, or maps created on site by Versabots’ auto-mapping functionality as process “canvas”. Using available CAD-based layouts enables customers, who have not yet decided to implement the AUTONOMY@WORK platform, to investigate the process improvement opportunity and the business case for smart intralogistics. The baseline model covering all aspects essential for process performance can be created quickly with user-friendly visual modelling tools.

The simulation engine accurately reflects the Navigational AI algorithms of individual simulated Versabots, as well as the functionality of the Multi Robotic System component of the AUTONOMY@WORK platform. This allows for detailed analysis of various aspects of Versabot utilisation: idle time, recharging time, coordination overheads, and mission execution times.

VERSABOX VIRTUAL FACTORY™ models are fully compatible with process models managed by the AUTONOMY@WORK platform. For clients who have implemented the platform, VIRTUAL FACTORY becomes just another component of the smart intralogistics toolset. But even if VIRTUAL FACTORY is used as a business case investigation tool before the actual implementation of the AUTONOMY@WORK platform (e.g. to determine the optimum configuration of the system), the defined models can be used as starting points for implementation, protecting clients’ investment in model development.

Implementing Virtual Factory

The modeling and visualisation tools will give you in-depth understanding of the AMR enabled intralogistics process. All you need is shop floor layout and basic requirements for the process efficiency (average cycle times and average payload estimates). Do not hesitate to contact VersaBox and book a free Virtual Factory Tour.

Taking existing shop floor layouts as input, managers can run virtual “run and rate” experiments, where they define the process topologies (endpoints, paths, charging stations)for potential new implementations of AMR-based intralogistics.

Intralogistics specialists can use simulations to optimise the process that will actually be implemented on a given site to shorten the implementation process and avoid master process disruptions.

When planning changes in an intralogistics process due to changing requirements, specialists and operation managers can investigate the optimum re-configuration, taking advantage of historical data concerning shop floor traffic.

Please contact us, we will be happy to answer your questions and prepare an interesting offer.