This post is also available in:

![]() PL

PL

If you plan to transition from traditional intralogistics to one based on Autonomous Mobile Robots (AMRs), you choose a gradual elimination of the “human factor” from logistics processes, which will reduce labour costs in turn. You will achieve the goal of eliminating randomness in favour of increasing predictability. At the same time, you will achieve the desired precision of process planning and the effectiveness of process control.

“Big” logistics, that is land, sea, and air transport, are shifting towards automation. Land transport will most likely get revolutionised first. Work on autonomous trucks is so advanced that “any minute now” we might see thousands of driverless trucks on motorways and highways. So why is it still a matter of the future? This is not because of a lack of adequate technology, but because of the reluctance of the logistics industry and the difficulties of international cooperation. “Small” logistics, or intralogistics, are not faced with the same problems. The revolution has already started in warehouses and production halls. It grows in strength each year, and even each month.

AMR intralogistics – an alternative to traditional internal transport systems

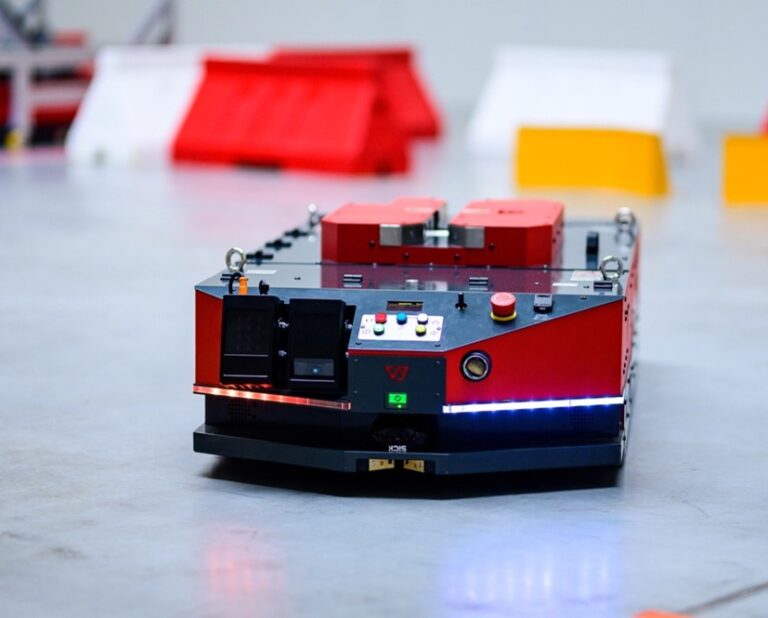

VersaBox is a manufacturer of Autonomous Mobile Robots (AMRs) which are an alternative not only to traditional intralogistics based on conveyors, industrial tractors, and forklifts. Despite many similarities, it is also a new solution when compared to Autonomous Guided Vehicles (AGVs). AMRs are truly autonomous: they are off the leash of direct and remote control. The do not have to follow designated paths – all they need is a specific destination, and the rest they will take care of themselves. They operate exactly as independently as people. The only difference being that they work faster, more accurately, and without break.

By implementing AMRs, you gain an opportunity for a comprehensive optimisation of internal transport. The differences between traditional and AMR-based intralogistics will be outlined in three sections: planning and implementation of logistics processes, their execution, and control.

Fast and low-cost process planning and implementation

Traditional planning, done “on paper” and based on human work, will force you to consider possible absences (holidays, illnesses, terminations), shift hours in compliance with employment regulations, and many other “human” variables. An implementation based on the physical assembly of machines or process testing is incredibly costly and time-consuming. The only way to avoid mistakes and failures is to rely on the experience and expertise of others, although that is not always effective. The planning and implementation of intralogistics systems based on AMRs is entirely different.

The most important thing is to use virtual models. Process building, testing and optimisation can be done without any real-world consequences. This is a very effective way to detect and eliminate bottlenecks in intralogistics before those bottlenecks generate losses in the “real world”. The cost of testing done on a virtual model is but a small fraction of the expenses to be incurred to set up a logistics process in reality. A well-thought-out and well-tested design is quick to implement, which further reduces costs.

Reducing labour costs of logistics tasks

Robots guarantee full repeatability of processes within any given length of time, performance continuity, elimination of errors, i.e. turn every disadvantage of human labour into an advantage. A more detailed overview of the impact of AMRs on labour costs can be found in the article “An expensive robot is cheap“.

Automation of internal transport enables full control in real time.

The further the automation goes, the greater the possibilities of process control and the greater the management precision (including remote management). It becomes easier to make adjustments and quickly develop alternative solutions on a virtual model. Automation also enables ongoing control of machine operation. The effect: an immediate reaction to any irregularities, and even the possibility of predicting them. Intralogistics systems that use AMRs provide an opportunity for predictive maintenance.

In the context of AMR capabilities outlined above, it is no wonder that their popularity within the industry is booming. They are gradually becoming a part of every branch of manufacturing. Currently, they work alongside people. However, their development will naturally lead to them taking over all internal transport tasks.

Industry 4.0: widespread automation of warehouses and factories

The German model is the most popular and well-supported automation model, and it emphasises the benefits of cooperation between robots and humans. The arguments put forward by the supporters of the cooperation model are all very rational and simply common sense. They are based on the idea that robots will take over monotonous, burdensome, and often dangerous work. This will allow people to focus on the roles of managers, programmers, engineers, and maintenance.

This model is an accurate description of what is currently happening in different sectors of manufacturing. We have embarked on a path leading to widespread automation using autonomous and intelligent machines. In other words, we are approaching a model known as Industry 4.0 and called the fourth industrial revolution.

Summary

There is no doubt, even now, that the goal, the aim of automation and robotisation is to eliminate the need for people to work physically. If we want to keep up with the competition, as entrepreneurs, we are forced to cut costs and get rid of the weak links in manufacturing and logistics processes. And labour costs are a tantalising prospect and an optimisation goal that has remained unchanged for decades. So far, corporations have relocated their factories to places where labour costs are lower than in Europe or the USA. There is currently no need for this. Robots, the cheapest workers in the history of civilisation, are available “on the spot”, wherever we need them. Today we cooperate. Tomorrow they might send on an indefinite holiday.