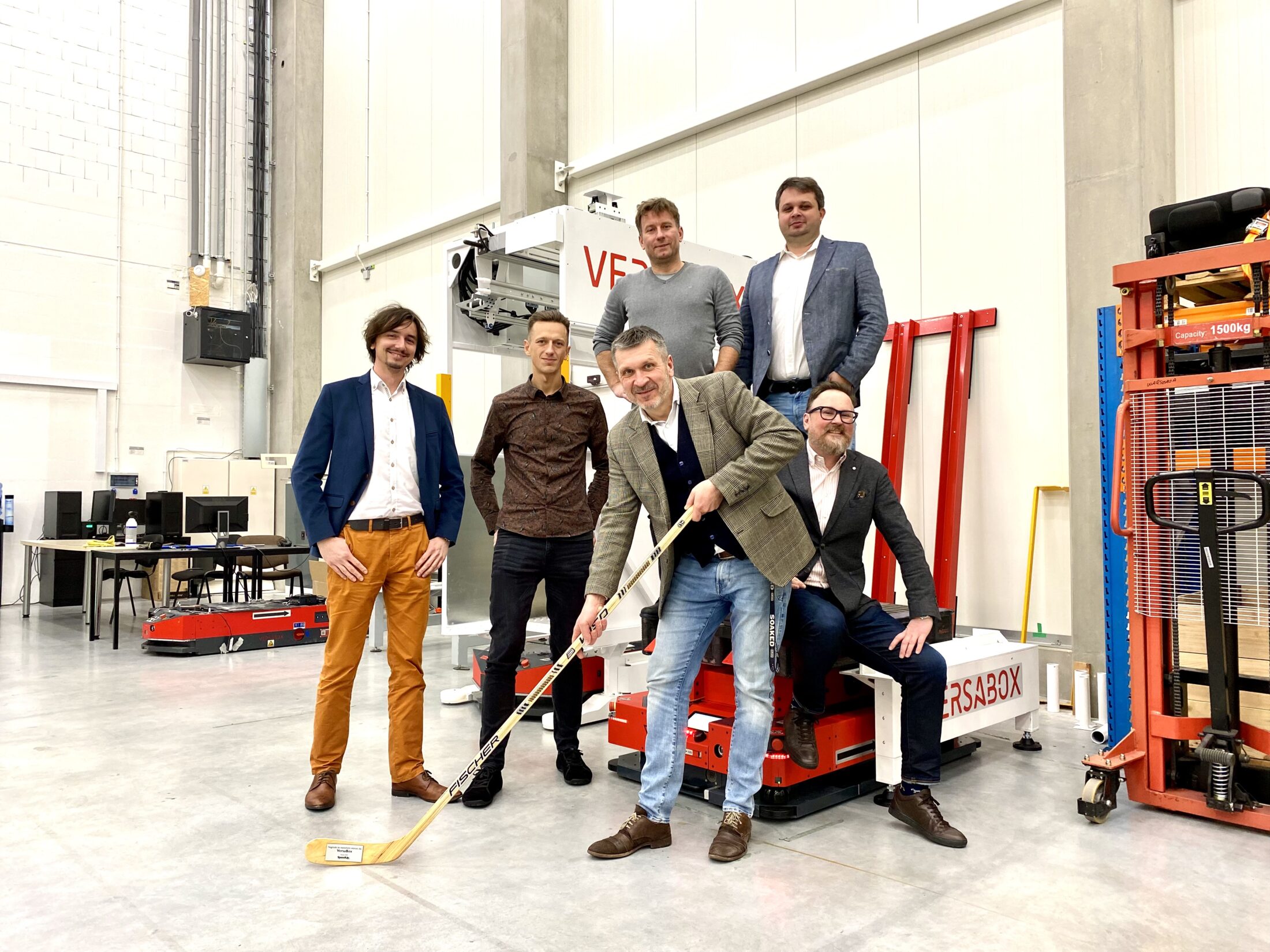

We implement intelligent intralogistics solutions using the AUTONOMY@WORK platform and AMR and AGV robots.

VersaBox offers flexible solutions for work autonomy. Our catalog includes autonomous robots, system platforms, simulation tools, autonomous pallet trucks, lifting modules, automatic coupling modules, power supplies and mobile service support.

The result of the work of VersaBox engineers is the AUTONOMY@WORK platform, which covers the entire AMR system implementation process. The core of the platform are autonomous mobile robots powered by TRUE AUTONOMY AI technology.

AUTONOMY@WORK uses digital twin technology to design all details of the intralogistics process. Simulation tools help you model processes for optimal work efficiency. Analyzing and comparing multiple scenarios in the virtual world is much cheaper and faster than doing it in physical operations.

VersaBox intelligent machines perform all assigned tasks, working every day and every night.