This post is also available in:

![]() PL

PL

The global e-commerce market records double-digit growth year-on-year. This has led to a sharp increase in demand for warehousing space and services. Warehousing services using traditional technology are becoming insufficient. This in turn has led to an increased interest in automation and robotisation of intralogistics. We present the three most important reasons for the rapid increase in demand for Autonomous Mobile Robot (AMR) collaborative robots.

Manufacturing and logistics are sectors where robotisation and automation are developing the fastest. Even in the first decade of the 21st century, the robotisation of intralogistics was a completely novelty. It is currently becoming a necessity – a requirement for effective development and successful business competition. The main reason for this is the development of the e-commerce industry, which in turn stimulates the growth of intelligent intralogistics.

Reason 1: Rapid growth of e-commerce

The driving force behind the demand for AMR and AGV collaborative robots is the incredibly dynamic development of the e-commerce industry. This is a common and undisputed theory, supported by strong evidence that came from the coronavirus pandemic. Contrary to initial concerns, 2020 turned out to be a period of incredible growth and huge profits for the e-commerce sector. Companies that managed to transfer their sales from physical stores to online shopping recorded their highest turnovers in years instead of losses.

The boom didn’t apply to all sectors of the economy. The automotive industry, which has had the largest share of the industrial robots market for years, didn’t benefit from the pandemic in any way. Nevertheless, the demand for AMR-class collaborative robots hasn’t decreased. Sales of industrial robots didn’t slow down despite the lockdown. Forecasts for the upcoming years are more than optimistic.

The sequence of causes and effects that have driven the industrial robots market over the last 12 months can be recreated as follows: the pandemic locks people in their homes, shopping shifts almost entirely online, e-commerce generates huge demand for warehousing space and shipping services, and this fuels interest in automation and robotisation. As many commentators have rightly pointed out, the pandemic didn’t create new trends or processes, but simply accelerated already existing ones. In the case of industrial robots, including mobile collaborative robots, the pandemic popularised the idea that the robotisation of logistics and intralogistics is not an option or a possibility, but a necessary requirement to meet ever-growing demand.

This trend is not only expected to continue but gain more momentum. In 2019, the value of the global e-commerce market was estimated at $3.5bn. This number is expected to double by 2026. This is also an excellent forecast for the AMR collaborative robot industry.

Reason 2: Constant increase in labour costs

The development of the e-commerce industry is not the only driving force behind the development of the collaborative robots market. Interest in robotics goes hand in hand with rising labour costs and difficulties in recruiting qualified machine operators, including industrial handling vehicles. In highly developed countries, the annual salary and personnel costs (remuneration, social benefits, insurance, training, etc.) of a single machine operator amount to $40,000-50,000. And you have to consider that you need three, or rather four, operators for a machine to be able to work three shifts non-stop.

For decades, large manufacturing and logistics companies have optimised their costs by relocating their operations to less developed countries. Corporations moved their businesses to China and other Asian countries, where labour costs were up to several times lower than in Europe or the United States. However, this way of cost-cutting is already on its way out as we speak. Suffice it to say that China has ceased to be a supplier of cheap labour. Not only that – but they are also developing into a global leader of new technologies, including automation and robotisation of all sectors of the economy.

Robots are a new cheap workforce. Going back to salary and social benefits costs of forklift operators, it’s easy to see that one AMR collaborative robot can amount to well over $100,000 in savings per year. In addition, collaborative robots offer something that no human staff can provide – independence from the economic situation on the labour market. You have to find an employee, recruit them, negotiate with them, and you also have to take account any random accidents and the possibility they’ll quit their job. All you need to do is buy enough collaborative robots to suit your current needs.

Read also: Why is an expensive robot cheap?

Reason 3: Gradually decreasing costs of intelligent intralogistics

For years, the use of collaborative robots has been dictated by the desire to improve the quality and efficiency of operation. However, many companies couldn’t use this solution due to the prohibitive cost. The situation has changed over the last decade. This doesn’t mean that robots have suddenly become very cheap, although the economy of scale does have an effect and initial costs are steadily decreasing. What’s far more important is that the robots have more and more functions and are easier to implement. It’s also crucial that new technologies allow you to reduce the risk of failure when investing in robotics.

AMR collaborative robots offered by VersaBox are a good example of the abovementioned issues. VERSABOT 500 and VERSABOT 1500 have a very cost-effective investment entry threshold. This is due to an attractive unit price, but also the ability to easily scale the investment, starting with a single machine.

The second important feature of VERSABOTs is that they can be deployed in any manufacturing or warehousing space. Their implementation doesn’t require any expensive changes to the infrastructure.

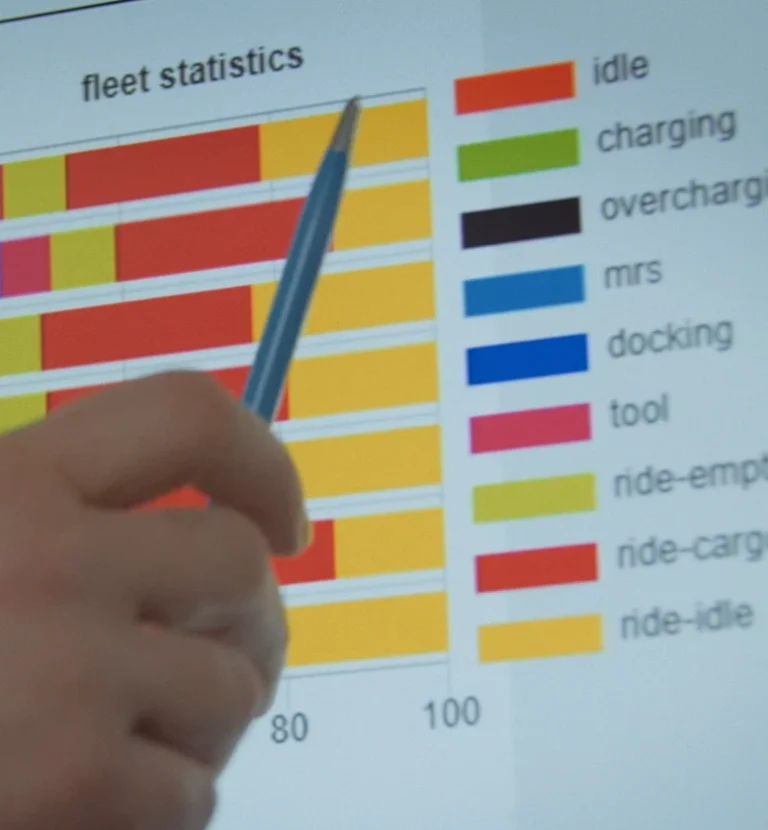

The third crowning argument is the functionality of the AUTONOMY@WORK™ system, which allows you to manage your fleet but more importantly create a virtual model of the intralogistics system. This allows you to test or validate and optimise the system before it’s implemented in the real world.

It’s worth adding that using the potential of virtual models doesn’t require an investment in an IT infrastructure. Computing power, disk capacity, and the software itself are all available in the cloud (cloud computing) using the SaaS model (Software as a Service): all you need to do is simply purchase a subscription and own a device with Internet access.

Summary

The reasons for the rapidly growing demand for AMR-class collaborative robots are the e-commerce boom, rising labour costs, and a reduction in robotisation costs. All of these factors are well-known and will continue to intensify. This means that investing in the robotisation of intralogistics using AMRs is becoming a necessity before our very eyes. Development is impossible without robots, and soon it will be impossible to survive without them at all.