Although AMRs have great potential, they’re not a magic bullet to solve all logistics problems a company may have. Each implementation of an autonomous robot brings measurable benefits. The range of benefits is closely linked to the types of tasks the AMR will perform, the level of organisational culture in a particular company, and even the current situation on the labour market. In this article, we discuss five issues that every business owner should consider before deciding to implement AMRs.

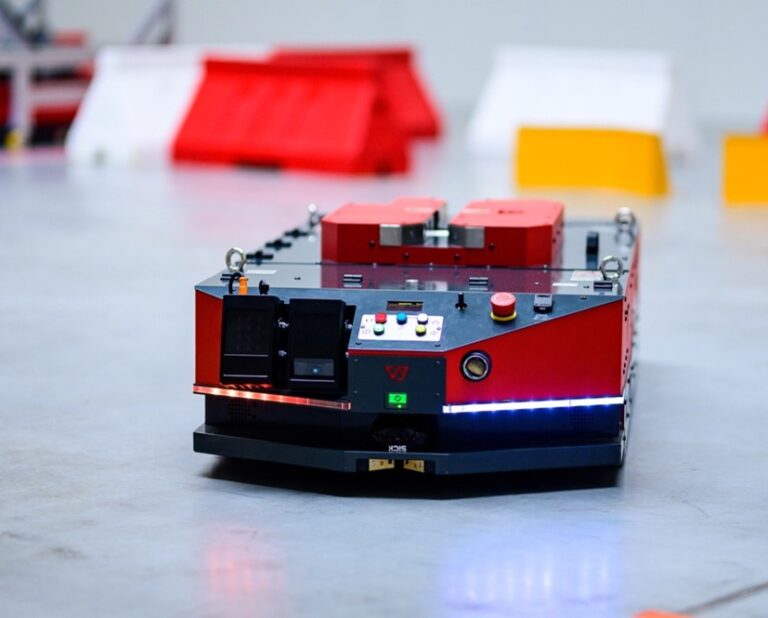

The basis for a successful implementation of autonomous robots is understanding how they operate. A solid grasp of the capabilities of robots like VERSABOT 500 or VERSABOT 1500 enables you to make the most of them.

1. AMRs enforce workplace culture improvements

Autonomous robots require a high level of workplace culture. The more respect for health and safety regulations, cleanliness, and tidiness at working stations, the less problems the robot has with performing its designated tasks. Cluttered aisles, abandoned pallets along routes, blocked payload collection or delivery points – all of these have a negative effect on the robot’s performance. Small shortcomings add up and may make the robot fall short of the expectations placed on it, of increasing the efficiency of transport processes.

The general amount of theoretical knowledge about robots and robotisation also have an influence on the operations of an AMR. If the staff has at least a basic understanding of the subject, they will be much more open to cooperation with machines. Otherwise, a lot of time is needed to get used to the “foreign body” that the autonomous robot appears to be. It’s also necessary to build trust in the machine, e.g. that it’s completely safe for humans.

Simply put – a company’s workplace culture and a robot’s efficiency are inextricably linked. The sooner we understand this, the better the results of AMR implementation will be. If the technical standards in a particular company aren’t very high, and the workplace culture is not clearly defined, the robot creates the conditions for a positive change.

2. Better to start with a fleet of autonomous robots than a single machine

It seems that the safer investment option is to introduce one or two robots, and then gradually expand the fleet. This is an option that may bring good results in the long run. However, if you want a spectacular change in quality, you should choose the opposite tactic. That means introducing exactly as many robots as will be eventually needed, all at the same.

Of course, buying an entire fleet “blind” could end in a financial and organisational disaster. However, you don’t have to take such risks, you can simply run precise simulations of various intralogistics solutions with AMRs using the VERSABOX VIRTUAL FACTORY™. Before intelligent machines are introduced into a real manufacturing plant or warehouse, you can trace their performance on a virtual model. The software created by VersaBox enables not only the design but also the optimisation of the internal transport system before its implementation.

3. Intelligent machine works three shifts

VersaBox is a manufacturer of autonomous mobile robots that can easily operate in a three-shift system. As a result, they replace the work of three people, e.g. forklift operators. Additionally, an AMR doesn’t generate labour costs comparable to humans, and its maintenance and repair is very simple and relatively cheap. This is a huge potential that could be achieved by virtually any industrial plant today.

At the same time, you should remember that the implementation of AMRs doesn’t exclude the use the of other handling equipment. AMRs are unrivalled when it comes to horizontal transport, but forklifts will still be needed for collecting and delivering goods onto high shelves.

4. Artificial intelligence can’t replace invention or working organisation

AMRs are truly autonomous machines. The robots themselves and the management system both make use of elements of artificial intelligence. VersaBox offers AUTONOMY@WORK™, a complete environment with modules for terrain mapping, process design, their optimisation, implementation and asset management. These are an efficient and effective set of tools that make designing an internal transport system and programming of robots accessible even to people without programming skills. It doesn’t change the fact that the end result depends on the creativity of the creator.

A robot is tireless, precise, and always ready for action. However, it will not do anything beyond what the system designer has taught it. AMRs have a great potential but cannot create an efficient intralogistics system on their own. Planning and design are our jobs as humans.

5. Robots don’t steal people’s jobs

The assumption that robots steal people’s jobs is not supported by facts. Experiences from industrial plants that have introduced AMRs shows that their presence actually improves the social security of employees and allows the recruitment of new people. Robots stimulate growth, strengthen a company’s position, and eliminate the risk of layoffs.

AMRs are a challenge for the human staff, but at the same time they’re an opportunity to move away from repetitive physical labour and focus on things that require creativity or innovation. Robotisation, therefore, enables the creation of better paid positions with more responsibilities, and also gives the employees the opportunity to develop their individual careers.