This post is also available in:

![]() PL

PL ![]() DE

DE

VIDEO

VIRTUAL FACTORY

Virtual Factory

AUTONOMY@WORK

AUTONOMY@WORK

SMART INTRALOGISTICS

Smart Intralogistics

VERSABOX

VERSABOX Overview

FAURECIA CASE

Case - Faurecia

PADMA CASE

Case - Padma

SMOOTH & EFFICIENT - FAURECIA STORY

Faurecia Frames in Wałbrzych was looking for a way to improve the smoothness and efficiency of internal transport. That goal was to move from traditional material handling to intralogistics 4.0 based on Autonomous Mobile Robots (AMRs).

Read MoreAUTONOMOUS TROLLEYS IN A WAREHOUSE

AMRs allow you to optimise warehouse operating costs and increase efficiency at the same time. Find out what else autonomous transport trolleys have to offer.

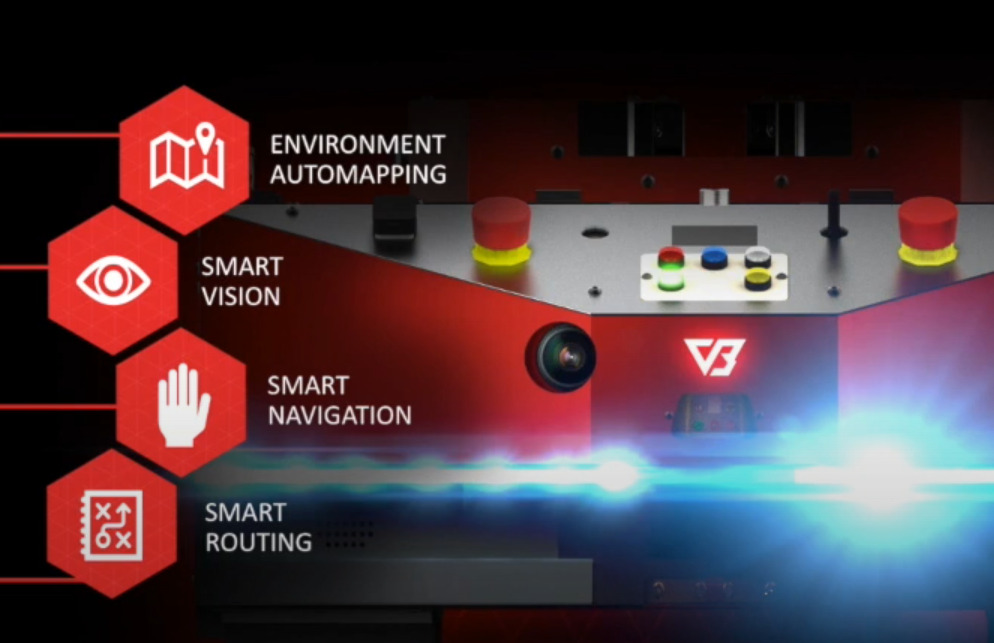

Read MoreMEET VB1500

VERSABOT 1500 is a new AMR in the VersaBox catalogue. Find out what transport capabilities it can offer and what makes it an even better robot than its predecessors.

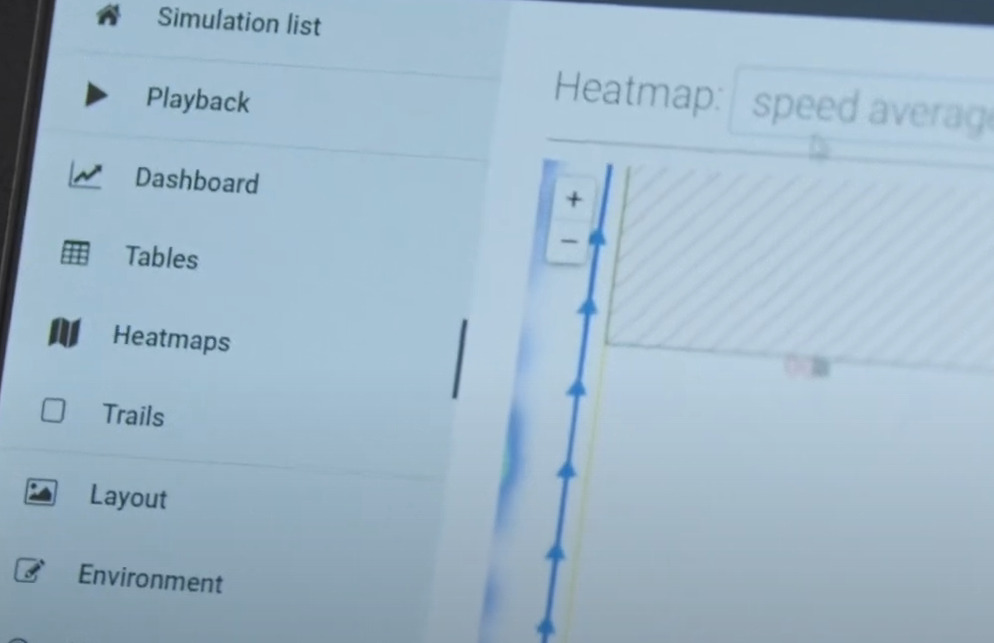

Read MoreDIGITAL RUN AT RATE

Simulation of an AMR implementation allows you to test any and all intralogistics processes before robots are deployed into the warehouse or production hall. Find out more!

Read MoreDOES EVERY FACTORY NEED A DIGITAL TWIN?

The virtual twin of a factory is a representation of the production hall, its equipment, and machines in the form of a digital model. Should every factory have one?

Read MoreAre AMRs eco-friendly?

Find out how autonomous robots help minimise our harmful impact on the environment.

Read MoreIntralogistics 4.0. Glossary of terms - part II

What is a manufacturing cell and what are intralogistic trains for? We explain the most difficult terms associated with the use of AMRs.

Read MoreHow does VersaBox do it? Comprehensive AMR implementation

VersaBox has created a system that allows customers to easily switch from traditional intralogistics to using AMRs. The solution is flexible and extensive.

Read MoreAMRs operate as a team, or how simulation supports intralogistics processes

The VERSABOT fleet is a team of autonomous, digital collaborators, managed by a central system.

Read MoreAutomotive industry personalisation using AMRs

Getting rid of human labour allows you to exclude the element of randomness. Robots maintain delivery time schedules without any delays, which means the entire manufacturing process becomes fully and easily controllable. In addition, robot labour is cheap and can go on for as long as necessary.

Read MoreAutonomous mobile robots in intralogistics. Trends and possible applications

When we talk about the use of autonomous mobile robots (AMRs), we usually think of warehouse or a production facility. This is due to the fact that industry and logistics generate the greatest demand for AMR-class machines.

Read MoreWHAT ARE AMRs ADVANTAGES? HOW TO IMPLEMENT SMART INTRALOGISTICS? WHERE TO START?

ASK OUR EXPERTS

CAREER OPPORTUNITIES

JOIN OUR TEAM

VersaBox is a Smart Robotics company. We bring together talents of new generation of innovators, software designers and engineers to develop world class, advanced technology solutions for the transforming global manufacturing and logistics. We put autonomy to work for our clients by implementing Smart Intralogistics platform based on autonomous robotic units. VersaBox solutions fill out the growing human workforce deficits with efficient, intelligent devices and enable productivity improvements through new generation of agile intralogistics processes (Intralogistics 4.0). We achieve this by implementing systems of collaborative autonomous robotic units, orchestrated by an innovative process management platform.